TMT Bars

TMT Bars That Are Simply Better.

Tulsyan Rebars are made in fully automatic mills with Blooms. They are certified by BIS, ISI, IS and CRM Belgium. The thermo-mechanic process is certified by TEMPCORE™ of Belgium, the world’s pioneer in TMT bars. We also roll to international standards such as – BS 4449, ASTM A GR 60 and SLS-375. At Tulsyan we produce bars from 6mm- 40mm, as per standards set by BIS, so our steel can be used for any requirement.

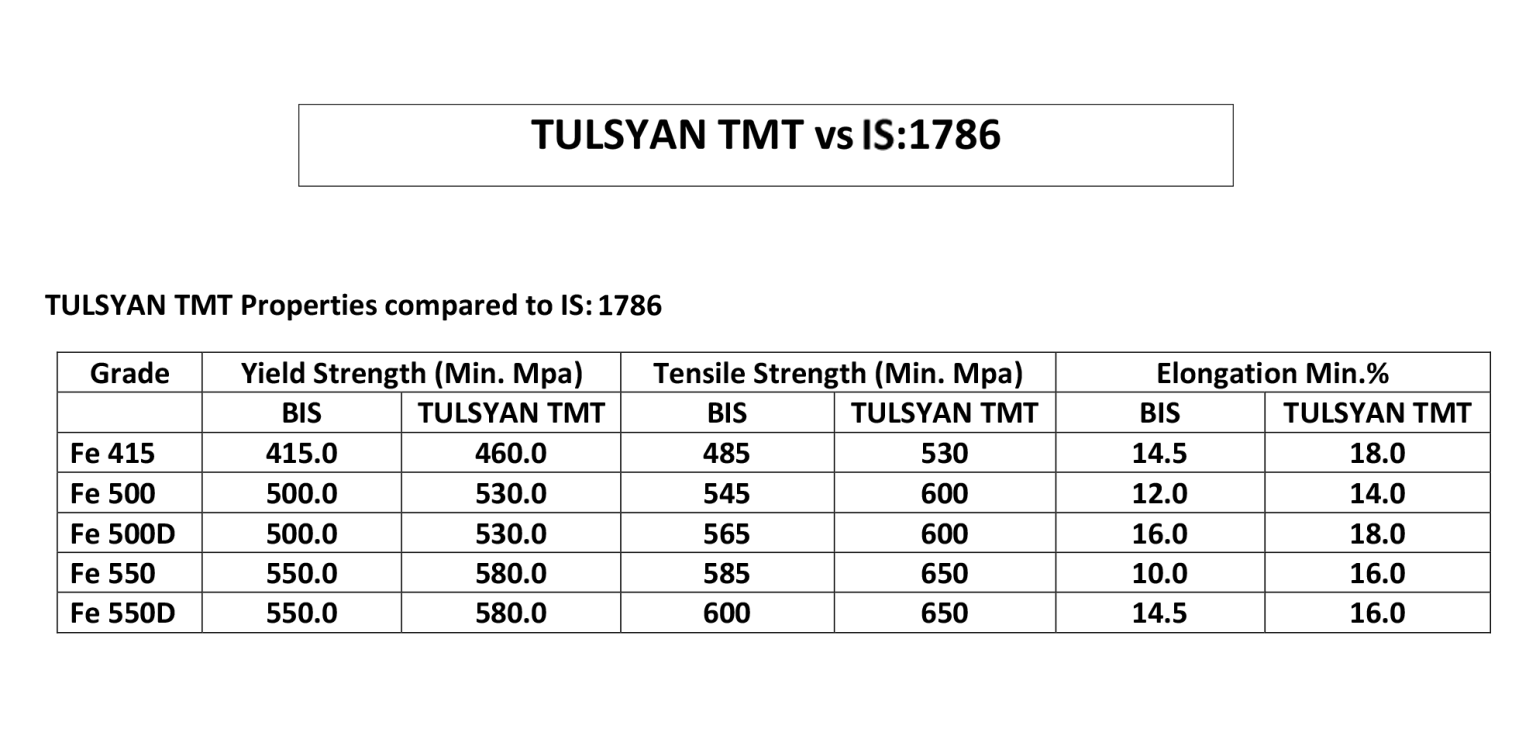

As seen above, at Tulsyan we maintain at least 10% better standards than those prescribed by BIS. We also manufacture HCRM (Corrosion resistant steel) and were one of the first to introduce this product. The HCRM bar resists corrosion 8 times more than a normal carbon bar, making the steel suitable for saline zones. This is done by adding specific chemicals and alloying elements.

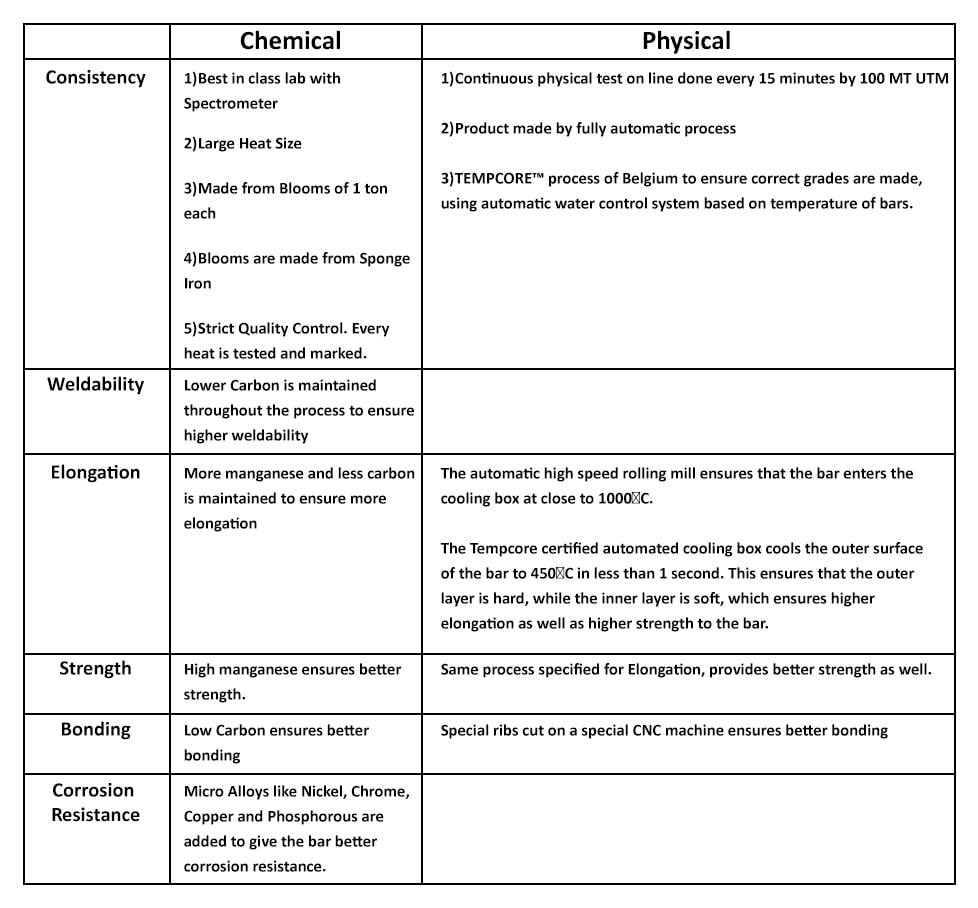

The main requirements of a TMT bar are Consistency, Weldability, Elongation, Strength, Bonding and Corrosion Resistance. Below are the ways Tulsyan ensures that every bar lives up to Tulsyan mark both chemically and physically.

TMT Crome Bar 3D

![]()

Tusyan Crome 500D HCRM is a breakthrough product for the steel industry, especially forged to withstand the forces of nature to ensure greater safety and stability.

When the process of steel rusting occurs due to hairline cracks in the concrete, the original volume of the steel bar expands up to 3 times resulting in the disintegration of the structure. While others make claims using epoxy coated steel and martensitic rim, the Tulsyan Crome rebar comes with a unique alloy mixture of Chromium (Cr), Nickel (Ni) and Copper (Cu) along with a thick tempered martensitic rim which improves corrosion resistance and fatigue strength of the bar to endure the acts of nature.

An exclusive X rib pattern, with greater rib depth and closer spacing, provides an even stronger and safer structure than conventional steel rebars.