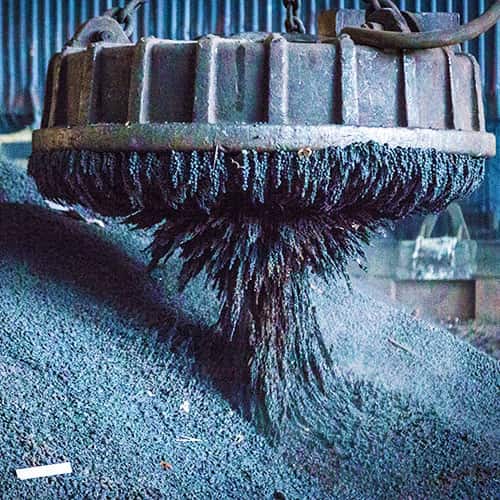

Sponge Iron

For Efficient Heat Transfer & Better Metallization Process.

Tulsyan Steel continues to make its mark in the industry. The Sponge Iron is another product that ensures Quality is of the highest essence when it comes to Tulsyan Steel.

Besides emphasizing on the supply of quality products, at Tulsyan Steel we focus on maximizing the utilization of the resources.

The material is also called as Direct Reduced Iron and the manufacture of Sponge Iron entails the de-oxidization of iron ore through the direct reduction. Direct Reduction is a process by which metallic iron is produced by the reduction of iron ore. Furthermore, it is produced from iron ore in the form of lumps, pellets, or fines.

Advantages of Sponge Iron:

- Chemical Composition is uniform

- It contains no undesirable impurities.

- It permits dilution with low-cost scrap.

- Easy to handle & transport.

- Permits automatic continuous charging.

- Less noise during the meltdown.

- More predictable price structure.

Sponge Iron has a variety of uses:

- Sponge Iron can be utilized as a substitute for steel scrap.

- It plays a pivotal role as feed material in all mini steel plants.

- Sponge Iron is an apt material as it can be utilized as a coolant in Integrated Steel Plants.

- Sponge Iron is manufactured by reducing iron ore without the melting process – thereby making it energy efficient.

The process is energy-efficient. Steel made using this particular process requires significantly less fuel, and the quality of the finished product is more consistent in terms of chemical composition. The sponge iron is used for internal consumption to produce Blooms.